Introduction:

The primary function of FurnXpert Level 2 software is to adjust the temperature setpoints so that the products are heated to the desired temperature for rolling. The software is designed to account for the following parameters.

- Part Speed

- Part Dimensions

- Part Grade

- Part Initial Temperature

- Part Target Discharge Temperature

General Overview:

The Level 2 software optimizes the heating of the products by adjusting the zone temperature setpoints.

The product tracking function tracks the products as they move through the furnace. A product locations with time is required for calculation of product temperatures.

The furnace profile along the length of the furnace represents the boundary condition for calculation of the actual temperature of the product. The product temperature is updated continually as the product moves through the furnace.

The actual temperature is calculated by the Thermal Mathematical Model.

The Temperature Setpoint Model uses product Ideal and Actual temperatures to determine the operating setpoint for each zone.

In addition to the normal operation, scheduled and unscheduled delay mode is also handled by Temperature Setpoint Models.

Thermal Mathematical Model:

Heat transfer takes place by radiation and convection between furnace and product surfaces and by conduction through the product thickness. The furnace temperature profile is obtained from the furnace thermocouples. The radiation and convection heat flux between the furnace and the product surface is calculated , considering emissivity of the waste gas, refractory and product surface.

The mathematical model consists of a finite difference heat transfer algorithm, which calculates nodal temperatures along the the thickness of billets at different positions along the length of the furnace. These temperatures are obtained by solving the system of heat transfer equations.

The mathematical model executes at a predetermined time interval or steps. At each calculation step, the model determines the amount of heat that has diffused inside the billets since the previous calculation step. The Heat Transfer calculations take into account Steel Grades, Product Dimensions, Charge Temperatures, Charge Positions inside the Furnace, Furnace Profile, and Product Temperatures at the last step.

Setpoint Model:

The setpoint Model determines the optimum setpoint for each furnace zone, based on the ideal and actual thermal state of the furnace and/or furnace operation. The setpoint calculations are based primarily on the steel temperature; therefore , variations in the furnace operation, production rate, product initial temperature, product target temperature size changes and grade changes are reflected in the setpoint calculations.

The setpoints are calculated at regular intervals normally 30 seconds. The zone setpoints are constrained by the temperature limits, available fuel, target temperature and other heating practices.

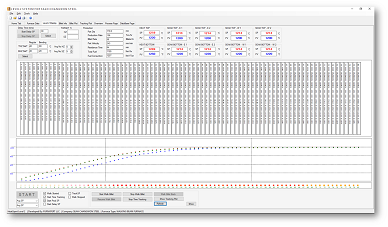

Simulator:

The purpose of the Level 1 simulator is to generate Level I signals just as one would see in an actual furnace control system. The signals could be the billet/slab/ingot walk rate or push rate, temperatures in each zones and from other thermocouples, air and fuel flow rates and any other parameters that are captured by the Level 1 system. These data are used by the Level 2 system to control the furnace.

Price of FurnXpert Level 2 Software:

The price of the software starts from USD 12,500. The price varies with furnace type, product mix, charge configuration, operational specificity.