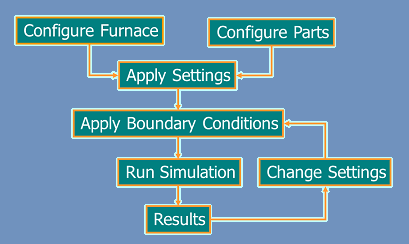

Modules for building a virtual Furnace includes

- Furnace Configurator: Furnace Dimensions, Insulations, Heating Mode, Burner Type

- Strip Configurator: Thickness and width of the strips or plates for each analysis

- Process Parameters: Production Rates, Strip Speed, Zone Setpoints

- Strip Placement: Provision to change strip length inside furnace

- Property Data: Steel Grades, Fuel Types and Refractory Material are included

- Property Data Creation: User can create their own property data

Results from the simulation includes

Part Temperature & metallurgy:

Results include Temperature profile of the strips along the furnace length and at exit, 2D skid marks for slab heating furnaces, Scaling/Decarburization depth

Heat Audit & Power Calculations:

Calculates heat to strips, refractory/wall loss, heat to gases, and heat and energy consumed in different zones, Heat loss through the flue, Zone wise fuel and air requirements and total fuel consumption and furnace efficiency. The results are displayed in a Sankey diagram.

Reports:

Results from each calculation can be displayed in report format. The results can be directly printed, saved as a PDF format or exported to an Excel spread Sheet.

View Screens - To view the screens please click on the screen shot below. It will walk you through all the furnction screens. If you mouse over the enlarged screen the forward abd backward scroll signs will appear.

Additional Modules

Setpoint Generator: This is an optional feature to calculate furnace zone setpoints for different sizes, grades, production rate, and furnace exit temperature of steel. The setpoints are calculated for steady state constant production rate and does not take into account any delays or mix of products inside the furnace.